How to Manage Inventory in the Warehouse

Sample of Document Content

This how to manage inventory in the warehouse template has 2 pages and is a MS Word file type listed under our business plan kit documents.

How to manage inventory in the warehouse

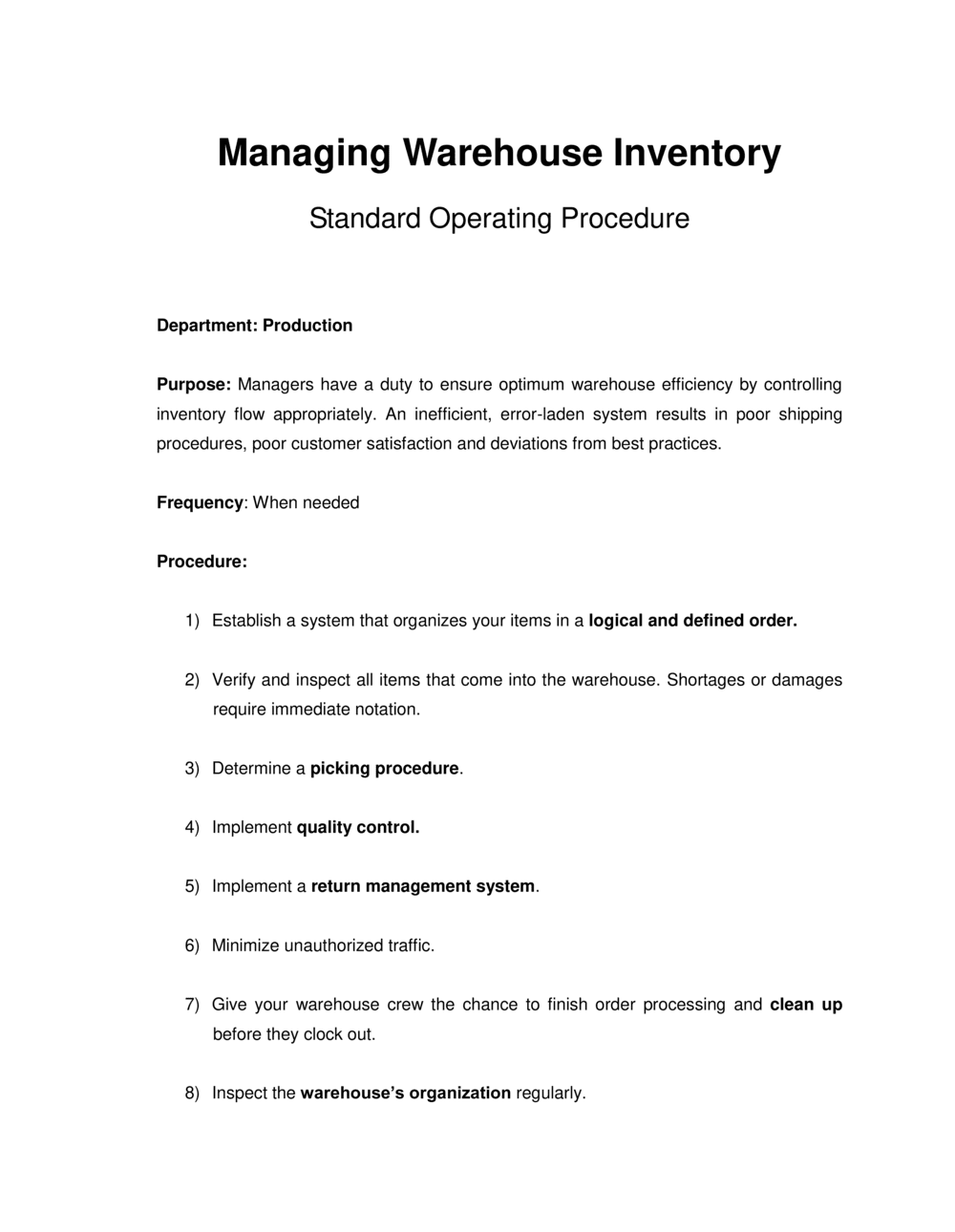

Managing Warehouse Inventory Standard Operating Procedure Department: Production Purpose: Managers have a duty to ensure optimum warehouse efficiency by controlling inventory flow appropriately. An inefficient, error-laden system results in poor shipping procedures, poor customer satisfaction and deviations from best practices. Frequency: When needed Procedure: Establish a system that organizes your items in a logical and defined order. Verify and inspect all items that come into the warehouse. Shortages or damages require immediate notation. Determine a picking procedure. Implement quality control. Implement a return management system. Minimize unauthorized traffic. Give your warehouse crew the chance to finish order processing and clean up before they clock out. Inspect the warehouse's organization regularly. Definition/Explanation: Logical and defined order: Keep the high-volume items in front and center of the warehouse, closer to the shipping area. Picking procedure: This will help maintain pickup times and ensure all shipments leave the warehouse at the correct time. Quality control: The process usually involves checking a picked item against an order to make sure it's the correct SKU (stock keeping unit i.e

Part of your Business Operating System

Reviewed on

Sample of Document Content

This how to manage inventory in the warehouse template has 2 pages and is a MS Word file type listed under our business plan kit documents.

Sample of our how to manage inventory in the warehouse template:

Managing Warehouse Inventory Standard Operating Procedure Department: Production Purpose: Managers have a duty to ensure optimum warehouse efficiency by controlling inventory flow appropriately. An inefficient, error-laden system results in poor shipping procedures, poor customer satisfaction and deviations from best practices. Frequency: When needed Procedure: Establish a system that organizes your items in a logical and defined order. Verify and inspect all items that come into the warehouse. Shortages or damages require immediate notation. Determine a picking procedure. Implement quality control. Implement a return management system. Minimize unauthorized traffic. Give your warehouse crew the chance to finish order processing and clean up before they clock out. Inspect the warehouse's organization regularly. Definition/Explanation: Logical and defined order: Keep the high-volume items in front and center of the warehouse, closer to the shipping area. Picking procedure: This will help maintain pickup times and ensure all shipments leave the warehouse at the correct time. Quality control: The process usually involves checking a picked item against an order to make sure it's the correct SKU (stock keeping unit i.e

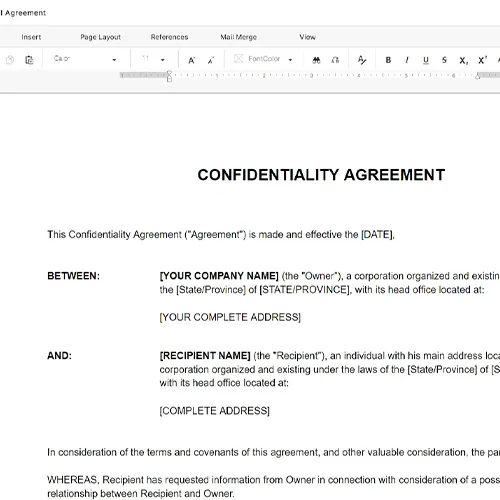

Create Standard Documents That Define How Your Business Runs.

Agreements, policies, and plans — all structured inside one Business Operating System.

Download or open template

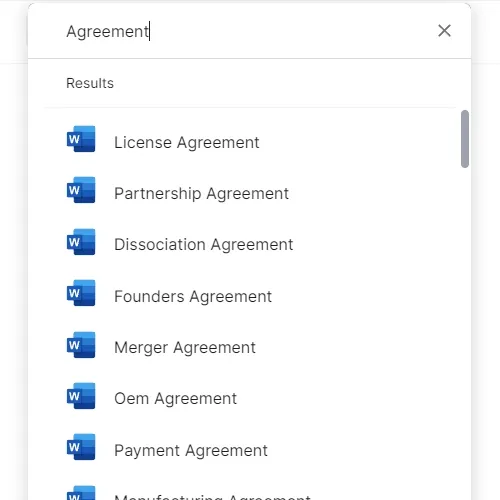

Access over 3,000+ business and legal templates for any business task, project or initiative.

Edit and fill in the blanks

Customize your ready-made business document template and save it in the cloud.

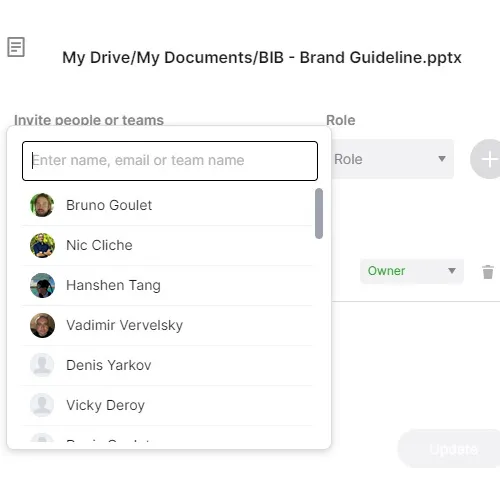

Save, Share, Export, or Sign

Share your files and folders with your team. Create a space of seamless collaboration.

Run Your Business With a System — Not Scattered Tools

Stop downloading documents. Start operating with clarity. Business in a Box gives you the Business Operating System used by over 250,000 companies worldwide to structure, run, and grow their business.